Accuracy and Precision in Concrete Scanning Solutions

Accuracy and Precision in Concrete Scanning Solutions

Blog Article

Introduce the Transformative Power of Concrete Scanning in Making The Most Of Performance and Security

Concrete scanning has actually arised as an important device in the building industry, providing unparalleled advantages in enhancing project effectiveness and making sure safety and security standards. By making use of sophisticated modern technology, concrete scanning enables specialists to see past the surface, revealing surprise intricacies that can affect the architectural honesty of a building. The transformative power of concrete scanning hinges on its ability to provide real-time data and in-depth understandings, changing just how jobs are planned and executed. As we explore the details of this ingenious technique, a globe of possibilities opens, showcasing a brand-new period of building methods that prioritize accuracy and protection.

Importance of Concrete Scanning

Making certain the architectural stability and safety of building and construction jobs starts with the essential step of carrying out thorough concrete scanning. Concrete scanning is a non-destructive method utilized to identify and map subsurface aspects within concrete frameworks. This process is vital in identifying prospective hazards, such as rebar, post-tension wires, and conduits, that might be hidden within the concrete. By making use of innovative modern technologies like ground-penetrating radar (GPR) and electromagnetic induction, construction teams can properly situate these aspects without triggering any kind of damages to the framework.

Additionally, concrete scanning assists in maximizing project timelines and budget by preventing unforeseen costs and hold-ups that might emerge due to unpredicted blockages within the concrete. Eventually, investing in comprehensive concrete scanning is a positive strategy that improves both performance and safety in building projects.

How Concrete Scanning Functions

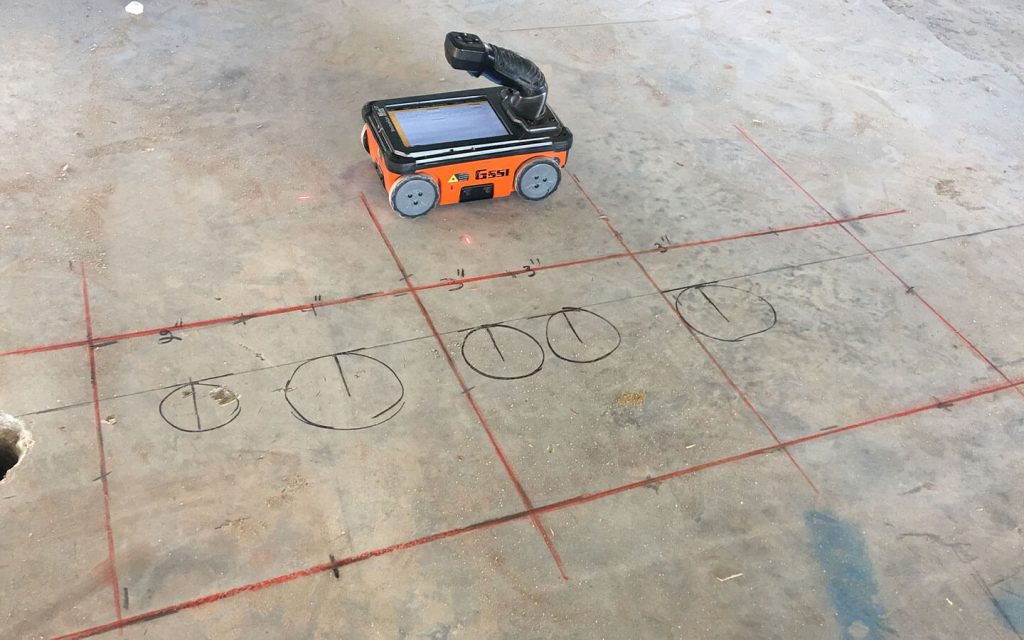

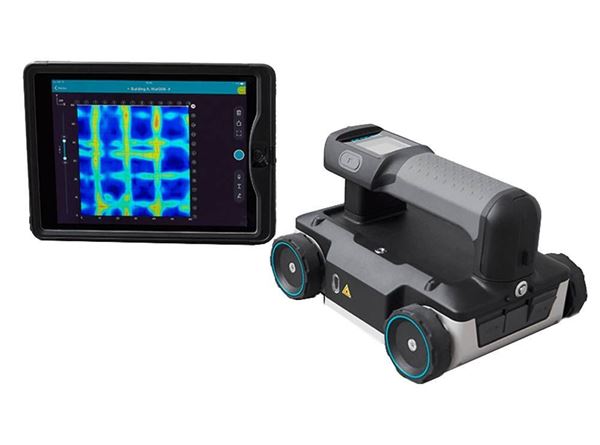

Concrete scanning operates as an important device in construction tasks by employing innovative innovations to find and map subsurface components without triggering structural damage. Ground Passing Through Radar (GPR) and Electromagnetic Induction (EMI) are two main methods utilized in concrete scanning. GPR works by emitting high-frequency radar pulses into the surface area, which get better when they run into subsurface items or voids. The time considered the signal to return indicates the deepness and area of the things. EMI, on the other hand, makes use of magnetic fields to determine differences in product compositions, such as recognizing rebar or avenues within concrete frameworks.

Throughout the scanning process, the information gathered is evaluated in real-time, enabling instant recognition of possible hazards or challenges underneath the surface area. This info help in decision-making, guaranteeing that building activities continue safely and successfully. Additionally, 3D imaging software application can be made use of to produce topographic maps of the subsurface aspects, additionally enhancing job planning and implementation. By utilizing these sophisticated modern technologies, concrete scanning dramatically minimizes the threat of expensive damages and injuries on construction sites.

Advantages of Concrete Scanning

One of the main benefits of concrete scanning is the capacity to identify and find embedded visit things such as rebar, post-tension wires, and conduits precisely. Concrete scanning helps in preparation and developing more effectively, as it provides precise information about the location and deepness of structural parts.

Study: Concrete Scanning Success

In one more instance, a building and construction company utilized 3D concrete scanning to examine the condition of maturing concrete frameworks in a historical structure. The comprehensive scans provided important understandings into the extent of wear and tear and helped focus on upkeep initiatives efficiently. By proactively resolving locations of problem identified with scanning, the business had the ability to expand the lifespan of the framework and make sure owner safety and security.

These instance studies underscore the transformative power Find Out More of concrete scanning in improving effectiveness, precision, and safety in building and construction tasks.

Implementing Concrete Scanning in Projects

Executing sophisticated scanning modern technologies during building and construction projects has actually come to be increasingly necessary for improving precision and safety. By incorporating concrete scanning into project planning and implementation, building and construction groups can determine prospective hazards, such as rebar or post-tension wires, concealed within concrete frameworks. This aggressive method minimizes the danger of crashes, delays, and costly rework, eventually leading to extra reliable job timelines and budgets.

To implement concrete scanning properly, job supervisors must team up closely with knowledgeable scanning experts to identify one of the most ideal scanning methods for the details job requirements. Involving scanning experts from the beginning of a job makes it possible for the team to create comprehensive scanning strategies that attend to crucial areas of problem and guarantee extensive data collection.

Moreover, including concrete scanning into normal job process can enhance decision-making processes, as real-time check data offers prompt insights into the problem of concrete frameworks - Concrete Scanning. This data-driven method helps with notified problem-solving and enables groups to make modifications quickly, fostering a culture of performance and safety and security throughout the project lifecycle

Final Thought

Finally, concrete scanning plays a critical duty in boosting efficiency and safety in building projects. By using innovative modern technology to discover and map out underlying frameworks within concrete, this process assists to stop expensive errors, make sure structural honesty, and decrease risks on site. With the ability to uncover covert elements and provide exact data, concrete scanning proves to be a useful device for enhancing project end results and making best use of overall success.

Concrete scanning is a non-destructive approach made use of to spot and map subsurface components within concrete structures. In addition, concrete scanning aids in enhancing job timelines and budget by preventing unexpected expenses and hold-ups that might arise due to unanticipated obstructions within the concrete. One notable instance study entails a large improvement job where concrete scanning played a vital duty in making sure job success.In an additional situation, a building firm utilized 3D concrete scanning to examine the condition of aging concrete structures in a historical structure. By incorporating concrete why not try these out scanning right into task planning and implementation, construction groups can determine potential hazards, such as rebar or post-tension cables, hidden within concrete frameworks.

Report this page